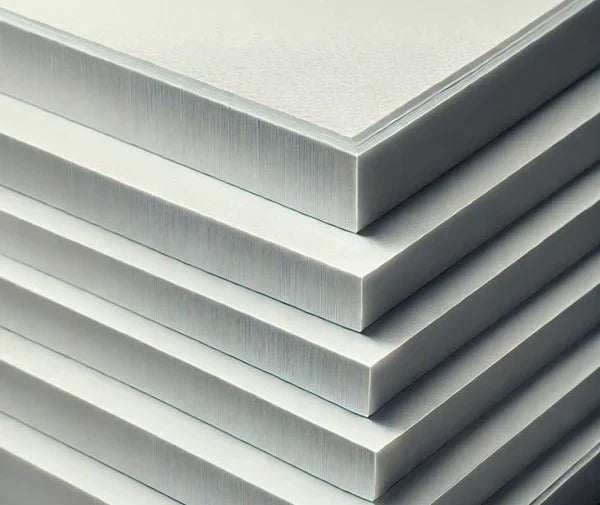

Everything You Need to Know About Polystyrene Sheets (EPS)

Polystyrene Sheets, commonly referred to as EPS (Expanded Polystyrene), are a versatile and practical material with a wide range of applications. Whether you're completing a DIY craft project, insulating a space, or creating custom displays, EPS sheets are a dependable choice. Known for their lightweight and insulating properties, they have become a staple in industries ranging from construction to design and art.

What Are EPS Polystyrene Sheets?

EPS stands for Expanded Polystyrene, a closed-cell foam made from polystyrene beads. These sheets are manufactured to be lightweight yet structurally robust, making them an excellent material for various applications. EPS is prized for its thermal insulation capabilities and shock absorption, adding great value in construction, packaging, and beyond.

Common Applications of EPS Sheets

Polystyrene sheets are incredibly versatile, making them suitable for numerous purposes. Here are some of their most common applications:

-

Packaging and Protective Shipping: EPS sheets are often used in packaging to protect items from damage during transit. Their shock-absorbing qualities make them ideal for fragile and sensitive items.

-

Insulation: Perfect for thermal insulation in buildings, EPS sheets are highly effective at maintaining desired temperatures and improving energy efficiency. They are great for walls, roofs, and even caravans or trailers.

-

Event and Display Design: From movie sets to exhibition backdrops, EPS sheets are a go-to material for creating temporary displays and props.

-

Crafts and Art Projects: Artists and hobbyists frequently use polystyrene sheets for custom projects. They are easy to cut, shape, and paint, making them highly adaptable for creative endeavors.

-

Model Building and Prototypes: EPS sheets serve as a reliable base for model making, mockups, and signage due to their lightweight nature.

-

Concrete Applications: These sheets are frequently utilised as void formers and moulds in concrete construction projects.

Key Features of EPS Sheets

When selecting a material for your project, understanding its key features is critical. Here’s what makes EPS polystyrene sheets stand out:

-

Lightweight and Easy to Handle: Due to their light nature, EPS sheets are incredibly portable and simple to work with.

-

Impressive Thermal Insulation: With excellent insulation properties, EPS sheets are an efficient solution to regulate temperature.

-

Shock Absorbing and Protective: Perfect for packaging and surface protection, these sheets safeguard items against impact or compression.

-

Customizable: EPS sheets are easy to cut, glue, and shape to suit unique needs. Custom shapes and sizes can also be tailored upon request.

-

Indoor and Some Outdoor Use: While primarily suited for indoor projects, EPS sheets can be protected for short-term outdoor use.

-

Variety of Sizes and Thicknesses: Available in several thicknesses, you’ll find an option suitable for nearly every project.

Advantages of Using EPS Polystyrene Sheets

Using EPS sheets comes with a myriad of benefits, particularly when compared to alternative materials. These include:

-

Cost-Effective: EPS sheets are budget-friendly, offering high performance without compromising quality.

-

Durability: Their resistance to moisture and physical stress ensures a long lifespan, even under demanding conditions.

-

Environmental Benefits: Many EPS sheets are recyclable and reusable, contributing to sustainability initiatives.

-

Versatility: Because EPS works for a broad spectrum of applications, it simplifies project planning and reduces the need for multiple materials.

How to Use EPS Sheets for Your Projects

Working with EPS is straightforward given how flexible and manageable the material is. Here are tips to help you make the most of polystyrene sheets:

-

Cutting and Shaping: Utilise a hot wire cutter, knife, or blade for clean and smooth edges, depending on your requirements.

-

Binding and Assembly: Use an adhesive suitable for polystyrene, such as spray glue or foam-safe options, for assembly.

-

Painting and Decorating: Ensure you use a paint that adheres well to polystyrene, avoiding solvents that could damage the surface.

-

Outdoor Applications: Apply a protective layer, like plaster or waterproof coating, to keep the sheets safe from weather exposure.

Final Thoughts

EPS Polystyrene Sheets offer unparalleled versatility, making them a practical choice for countless applications. From construction projects demanding insulation to innovative DIY projects, these sheets deliver on performance, ease of use, and affordability. Lightweight yet durable, they are a trusted material for both professionals and hobbyists. If you’re ready to start your next project, EPS sheets might just be the perfect solution.

With their customisable options and endless possibilities, the sky’s the limit when working with polystyrene sheets!