Comparing Foam Types: Polyurethane Foam, EVA, XPS, and Polystyrene Sheets

When choosing the right foam for your project, understanding the differences between materials can save time, money, and frustration. At Foam Supplies WA, we supply a wide range of high-quality Australian-made foam products — each designed to suit specific needs.

Whether you’re upholstering furniture, crafting props, insulating a wall, or building a marine cushion, the type of foam you choose truly matters.

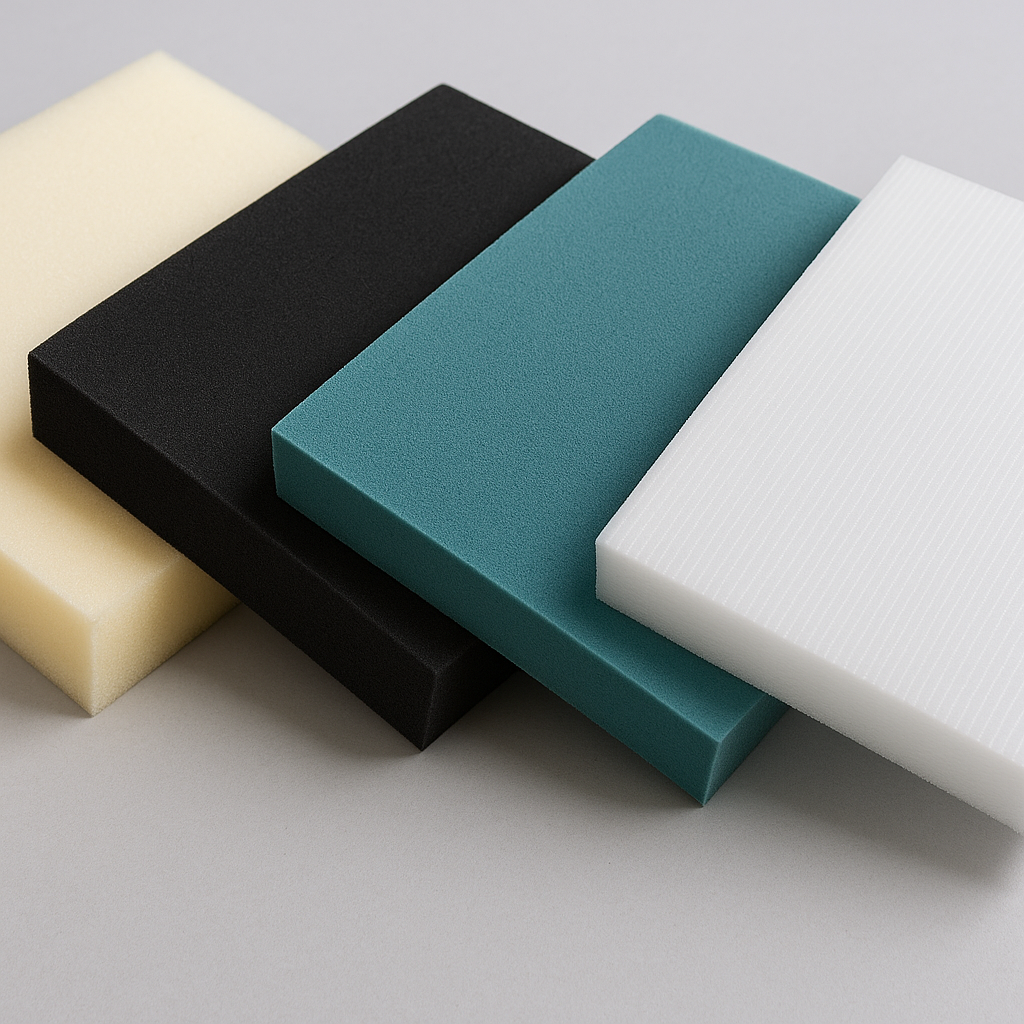

Polyurethane Foam: The All-Round Performer

Polyurethane (PU) foam is one of the most versatile and widely used foam types available today.

It’s flexible, affordable, and easy to cut, making it ideal for furniture cushions, mattresses, and packaging.

Key benefits:

-

Excellent cushioning and comfort

-

Wide range of densities available

-

Can be custom-cut to any size or shape

-

Breathable and suitable for indoor applications

Best used for: sofa cushions, bedding, seat pads, and general upholstery.

Tip: When selecting polyurethane foam, consider the density — higher density provides better durability and long-term support.

EVA Foam: Durable and Water-Resistant

EVA (Ethylene-Vinyl Acetate) foam is a strong, flexible, closed-cell foam that’s both shock-absorbent and water-resistant.

It’s perfect for environments where moisture or heavy wear is common.

Key benefits:

-

Non-toxic and soft to touch

-

Resistant to water, UV, and chemicals

-

Excellent impact absorption

-

Easy to cut and shape with precision tools

Best used for: yoga mats, marine seating, gym flooring, camping gear, and kids’ play mats.

Fun fact: EVA foam is often used in sports equipment and even costume armour — proving how tough yet lightweight it is.

XPS Foam: The Insulation Specialist

Extruded Polystyrene (XPS) foam is a rigid material primarily used for thermal insulation in building and construction.

It’s known for its closed-cell structure, which makes it highly resistant to moisture and excellent at retaining temperature.

Key benefits:

-

Strong thermal insulation properties

-

Resistant to water and mould

-

Rigid and lightweight

-

Long-lasting performance in extreme conditions

Best used for: wall insulation, under-slab insulation, and DIY construction projects.

Pro tip: When cutting XPS foam, use a fine-tooth saw or a hot-wire cutter for a clean finish.

Polystyrene Foam Sheets: Lightweight and Versatile

Polystyrene foam sheets (EPS) are lightweight, low-cost, and easy to handle.

They’re commonly used in crafts, packaging, and signage, but they also serve a role in insulation when cost-effectiveness is key.

Key benefits:

-

Inexpensive and widely available

-

Excellent for lightweight structural use

-

Can be painted, glued, and shaped

-

Recyclable in most regions

Best used for: craft displays, model building, packaging inserts, and basic insulation.

Note: EPS foam is less durable than XPS, so it’s not ideal for high-load or outdoor environments.

Which Foam Should You Choose?

Here’s a quick comparison to help decide:

|

Foam Type |

Texture |

Water Resistance |

Durability |

Common Uses |

|---|---|---|---|---|

|

Polyurethane |

Soft & flexible |

Moderate |

High |

Cushions, mattresses, upholstery |

|

EVA |

Firm & rubbery |

Excellent |

Very High |

Gym mats, marine use, play mats |

|

XPS |

Rigid |

Excellent |

Very High |

Insulation, building projects |

|

Polystyrene (EPS) |

Rigid & light |

Moderate |

Medium |

Packaging, crafts, basic insulation |

Why Buy Foam from Foam Supplies WA?

At Foam Supplies WA, we pride ourselves on offering Australian-made, high-quality foam products suitable for every project — big or small.

Our experienced team can custom-cut foam to any shape or size, provide expert advice, and ensure fast delivery across Western Australia.

Whether you’re replacing a couch cushion or insulating a new home, we have the right foam solution for you.

Contact Foam Supplies WA today to find the perfect foam for your next project!